一、设备参数

项目

|

规格

|

硬质合金锯片

|

¢360x60T

|

最大锯切规格

|

¢100mm |

送料长度

|

10 ~500mm |

丝杆送料精度 |

±0.02-0.03mm |

锯切面对轴线垂直度

|

≤0.2/100

mm

|

夹紧方式

|

水平垂直夹压

|

锯片转速

|

60/80/100/120RPM(无级变频)rpm |

电机功率

|

15KW(变频)

|

液压系统压力

|

30Mpa |

冷却方式

|

油雾润滑冷却

|

液压油箱容积

|

60L

|

液压电机功率

|

2.2/4PKw |

压缩空气

|

4-6bar |

排屑方式

|

自动链板式排屑系统

|

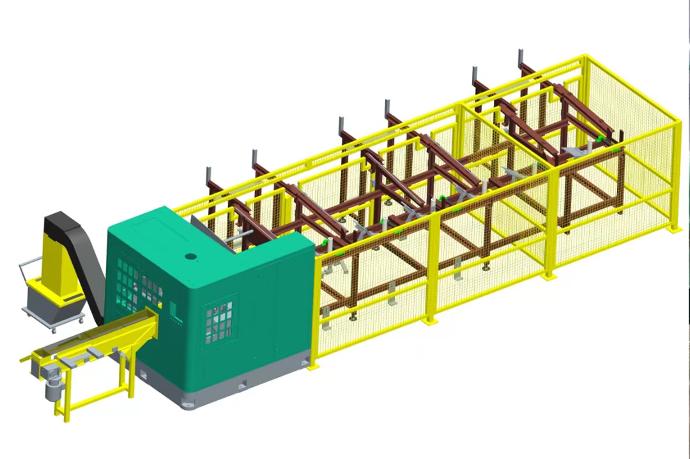

二、设备实拍

三、设备主要组成

S-100NC棒料高速锯切机,主要部件由机床床身、主轴部分、进给系统、夹紧装置、自动送料装置、滚筒式料架、液压系统、电气系统、冷却系统、刮板式排屑机等部分组成。

1、机床床身:床身主体由优质高强度特殊材料整体焊接而成,焊接后径整体去应力回火处理。具有整体刚性好、强度高、耐冲击、变形小的特点, 能大大提高机床的整体刚性和机床锯切稳定性。

2、主轴部分:齿轮箱采用优质高强度特殊材料整体铸造而成,强度高、耐冲击。高性能材料制成的主轴箱及主轴经过特殊热处理和精密的磨削,保证传动平稳和锯片平均使用寿命,传动效率高。轴承采用进口高精、高强度的进口轴承,使整个主轴箱运转噪声小、平稳、传动性能可靠。特有的锯片稳定锯片加持系统的采用,能大大提高夹持圆锯片的刚性,减少锯片的振颤、偏摆,使锯片的使用寿命得到更大的提高,锯切的精度和稳定性得到可靠保证。

3、进给系统:由伺服电机驱动丝杠带动主轴箱进行平切式强力进给,将被夹压的工件高精度快速切断。

4、夹紧装置:由两组水平与垂直的夹紧装置组成。前后两套装置可同时夹紧和松开,保证锯切过程的平稳性。

5、自动送料装置:自动送料采用交流伺服控制高精度滚珠丝杆的方式,使送料的精度得到可靠保证。

6、滚筒式料架: 滚筒式料架用于成排摆放待切原材料,最长可摆放长度4米的棒材料。可选用自动返料机构。

7、液压系统:由油箱、集中块、液压泵、液压元件、执行元件等组成,故障率低,性能可靠、稳定可靠地实现各种程序动作。

8、电气系统:由电器柜、触摸屏、按纽、PLC、电机、接触器、继电器、热交换器、开关和辅助元件等组成。机床可实现全过程数控,原材料摆放承料架后按启动按钮即可自动锯切作业。自动化程度高,各种安全保护装置能保证锯切线全过程的安全平稳运转。

9、冷却系统:采用微量润滑冷却润滑系统,达到快速冷却,降低生产成本,同时还可以提高切口质量,延长锯片使用寿命。

10、自动链板式排屑系统:采用自动链板式排屑系统收集锯切产生的锯屑,有效 改善车间环境,减少工人劳动强度。