一、设备参数

设备型号

| SDY-QFS600 |

电源电压

|

380V/50Hz

|

气源压力

|

0.5~0.8Mp

|

主电机功率

|

5.5KW(依据材料而定)

|

主轴转速

|

2850rpm(支持变频调速)

|

最大切割宽度

|

400mm

|

最大切割高度

|

170mm

|

切割精度

|

±0.1mm

|

锯片冷却方式

|

微量润滑

|

锯片规格

|

Φ 550mm 向下兼容

|

送料伺服电机功率

|

1.0KW

|

锯切进刀伺服电机功率

|

1.0KW

|

尾料伺服电机功率

|

750W(无尾料设备具备)

|

吸尘器功率

|

3KW

|

单次送料长度

|

1200/4000/6000mm(可循环往复送料)

|

设备外形尺寸

|

约6200*1500*1850mm

|

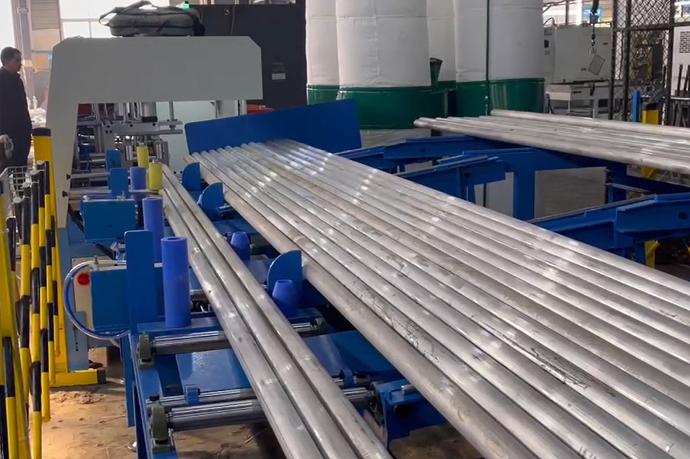

二、设备实拍

三、设备特点

1、设备工作台板采用专利结构设计,可有效保护材料表面;

2、采用同服电机驱动送料、锯切进刀、尾料处理,快速、稳定、可靠;

3、设备具备自动定位、自动润滑、自动锯切、自动分刀、自动尾料处置,操作方便;

4、设备程序具备安全门联锁功能,让操作变的更安全;

5、滚珠丝杆及导轨全部采用进口品牌,确保锯切加工的稳定性;

6、主轴精度控制在0.005mm以内,适配超薄合金锯片,节省材料浪费,并可反复修磨使用,为企业降低成本消耗;

7、设备具备自动上料功能,只需要将材料放置储料架上,设备自动获取材料,实现无人化生产;

8、可锯切多种截面形状的铝型材,铜以及pVc等材质。